Understanding the Thermography Printing Process

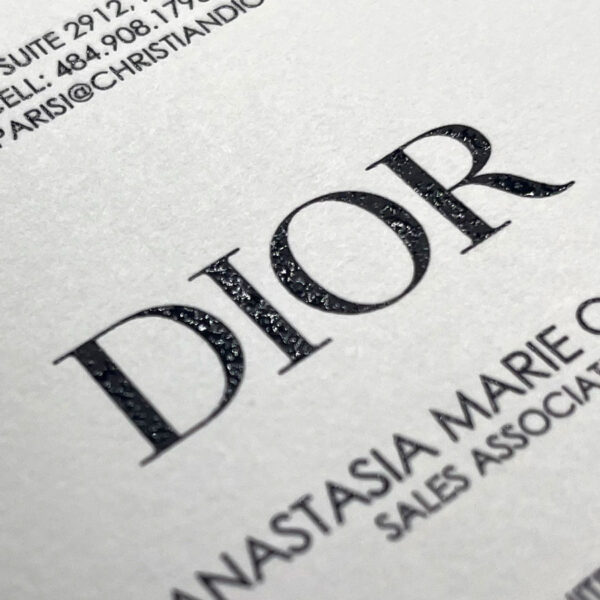

Thermography printing, often known as “raised printing,” is a popular and versatile printing technique that combines traditional printing methods with heat to create a distinctive raised effect on printed materials. This process is highly valued in the production of business cards, invitations, letterheads, and various other stationery items due to its elegant and professional appearance.

What is Thermography Printing?

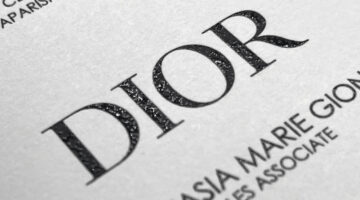

Thermography printing involves applying a special powder to wet ink on a printed sheet, which is then heated to create a raised effect. The result is a textured, glossy finish that gives a three-dimensional appearance to the printed text and images. This method is not only visually appealing but also adds a tactile element to printed materials, making them stand out.

The Thermography Printing Process

- Design and Prepress: The process begins with the creation of a design using graphic design software. The design is then prepared for printing, ensuring all elements are correctly aligned and in the desired colors.

- Printing: The design is printed onto paper using a traditional offset or digital printing press. It’s crucial that the ink used is slow-drying, as this allows the thermographic powder to adhere properly. The ink is applied thickly to ensure a sufficient amount for the powder to stick to.

- Application of Thermographic Powder: While the ink is still wet, the printed sheet passes through a device that dusts it with thermographic powder. This powder adheres only to the wet ink areas, leaving the rest of the paper clean. The excess powder is then removed, typically by vacuum or shaking, and recycled for future use.

- Heating: The sheet with the powder-coated ink is then conveyed through a heating unit. The heat causes the powder to melt and fuse with the ink, creating the raised, glossy effect. The temperature and duration of heating are carefully controlled to ensure consistent quality and avoid damaging the paper.

- Cooling and Finishing: After heating, the printed sheets are cooled to solidify the raised effect. The final step involves any additional finishing processes, such as cutting, folding, or packaging, depending on the intended use of the printed materials.